Have you ever wondered how a 4 stroke dirt bike engine works?

The four stroke engine is heavier and more complex than its two stroke cousin. There are between 30-50% more moving parts on a four stroke dirt bike engine. Plus they weigh more than its comparable 2-stroke counterpart.

A 4 stroke dirt bike engine works on a principle of four strokes or four cycles of a piston. There are two upward strokes and two downward strokes that make up the four strokes. These four strokes are called the intake stroke, the compression stroke, the combustion stroke and the exhaust stroke. On the intake stroke, the intake or fuel valves are opened to let an air-fuel mix into the combustion chamber. On the exhaust stroke, the exhaust valves are opened to let out the burnt fuel or exhaust created from the combusted fuel.

How a 4 stroke engine works on a dirt bike

A 4 stroke or four-cycle engine is a type of internal combustion engine. Four stroke engines are very much more complicated when compared to it’s cousin the 2-stroke dirt bike engine.

In the past, there were less dirt bikes made with four stroke engines than there were of 2 strokes. But this bias has shifted the other way. The reason why two strokes were preferred is because they are a lighter engine.

But having said that, modern four stroke engines have come on leaps and bounds. This means they are lighter and more efficient than they used to be. Dirt bikes with four stroke engines are now more powerful on a power to weight ratio than they were in the past. But even with all the advancements, a four stroke will never be able to compete power-wise with a two stroke engine.

Currently, most dirt bikes are made with a 4 stroke engine. I remember thinking 30-plus years ago when the 4 strokes started to come into dirt biking, that I’d never buy a 4 stroke. 2 strokes were much more poky (and still are) and had much better acceleration than the 4 strokes back then.

This is still the case of a two stroke engine. A two stroke engine can produce up to twice the amount of power than a four stroke engine of the same cylinder capacity. This is because it fires once every revolution, whereas the four stroke fires once every other revolution. For example, a two stroke 125 dirt bike would have similar power to a 250 four stroke dirt bike.

This leads to how a four stroke engine works.

How the 4 stroke cycle works

Before I explain the four-cycle process of a four stroke engine, I want to run through the basics of a four stroke dirt bike engine. These include the following:

- Intake manifold – The intake manifold is where the air fuel mix is fed from the fuel injection or carburettor system.

- Fuel injector – The fuel injector injects fuel into the intake manifold, which is where the fuel is mixed with air drawn in via an air filter. Older versions of a four stroke dirt bike will use a carburettor to feed the air-fuel mix, instead of the fuel injection system. Take a look at this article if you want to see why it’s important to clean your air filter.

- Intake or fuel in-let valves – The intake valves open at the correct time to let the air-fuel mix into the combustion chamber.

- Exhaust valves – The exhaust valves open at the correct time to let the burnt fuel or exhaust fumes out of the engine.

The four strokes of a 4 stroke engine

On a 4 stroke engine, the engine combusts on every other cycle of the piston. It’s called a four stroke engine, as it requires four strokes to complete a full cycle (see four stroke animated video below).

On the first stroke, the piston travels downward. As the piston travels down, the intake valve opens. The intake valve opening lets a certain amount of fuel, which is mixed with atmospheric air, into the combustion chamber. At the bottom of the first stroke and immediately before the second stroke, the intake valve closes. This first stroke is called the intake stroke.

On the second stroke, the piston now travels upwards. The upward motion compresses the air-fuel mix contained in the combustion chamber. The compressing of the mixture of air and fuel makes it highly combustible. The second stroke is called the compression stroke. At the point when the piston is at the top, or what’s known as Top Dead Centre (TDC), the spark plug fires.

When the spark plug fires, this ignites the air-fuel mix in the combustion chamber. The explosion of gasses causes high pressure and sends the piston down on its third stroke. This third stroke is called the combustion stroke.

As the piston reaches the bottom point of travel, which is referred to as Bottom Dead Centre (BDC), the exhaust valve opens. The piston travels back up the cylinder and pushes the exhaust fumes out through the exhaust valve outlet. The fourth stroke is called the exhaust stroke.

At the top of the fourth stroke, the exhaust valve closes and the intake valve opens and the cycle begins again.

A four stroke engine is more fuel efficient and better for the environment

Unlike the two stroke engine, where both the transfer port (from where the fuel enters the combustion chamber) and the exhaust port are open at the same time, with the four stroke engine the intake or fuel port and the exhaust port are controlled by valves.

The ports on a four stroke engine are only opened at the correct time during the four-stroke cycle. This means that less fuel is wasted in the combustion cycle. As a consequence, the four stroke engine is much more fuel efficient. Plus it produces less hydrocarbon emissions. Therefore, they are better for the environment.

The other environmentally friendly element to a four stroke engine is that it’s much quieter than a two stroke engine. For anyone that’s heard a two stroke at high revs, they will know what I mean by this.

A four stroke can also be very loud too. But the level of noise from the engine can be controlled by the type of exhaust system used.

The crankcase of a four stroke as a comparison to a two stroke engine

For comparison, the crankcase on a 4-stroke engine is full of lubricating engine oil. So the fuel on a four stroke engine doesn’t enter the combustion chamber via the crankcase like it does on a two stroke. Instead the fuel is fed directly into the combustion chamber via ports in the cylinder head.

The 2 stroke engine gets its lubrication from the oil mixed in with the fuel. So as the air-fuel mix enters the crankcase, which is ladened with oil, a certain percentage of the oil mixed in with the fuel remains on the moving parts and lubricates.

It’s important to make sure the oil in your four stroke engine is topped up in your crankcase. If you don’t keep it topped up, you could end up with a seized engine. This once happened to me and when I took the engine apart, the piston rods were completely seized to the crankshaft.

Most modern dirt bikes will have an oil pressure light. If the oil pressure light illuminates, stop riding your bike immediately. This light is signalling low oil pressure and if you continue to run the engine, it may well seize up on you like it did with me. I ignored the light for too long! Ignore your oil pressure light at your peril!

Animated video of a four stroke engine

I have included an animated video of a four stroke engine and how it works below.

The components of a 4 stroke engine

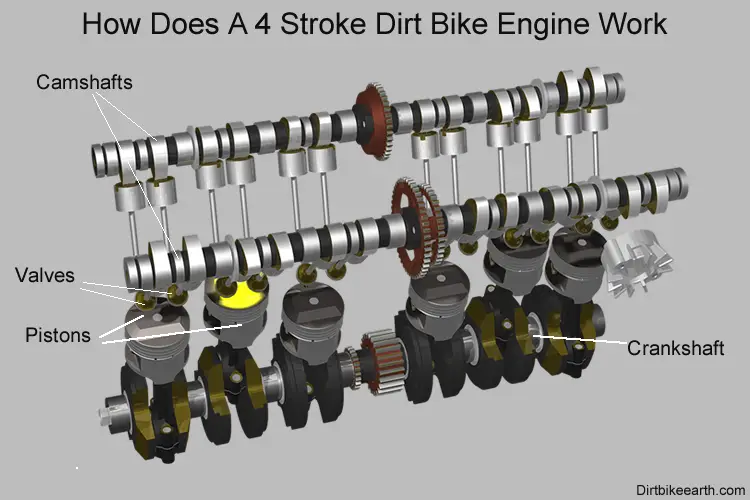

The components of a four stroke include the following:

- Piston – which forms the basis of the combustion engine.

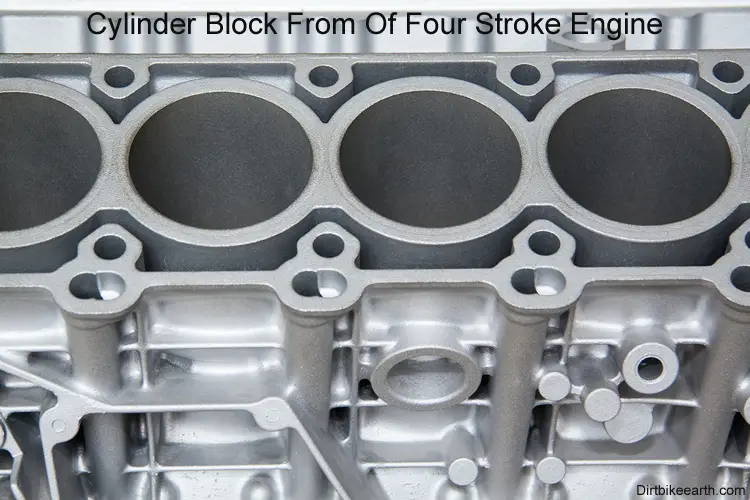

- A cylinder block and head – which is what houses the piston(s).

- Fuel valves – The fuel valves let an air-fuel mix into the combustion chamber.

- Exhaust valves – Let the burnt fuel (or exhaust fumes) out of the combustion chamber, which leads to the exhaust manifold and exhaust system.

- Camshaft – The camshaft rotates and is responsible for opening and closing the inlet and exhaust valves.

- Crankshaft – The pistons are connected to the crankshaft via the piston rods. The crankshaft is what drives the power via the clutch through to the gearbox and then to the rear wheel of your dirt bike.

I hope you enjoyed this article about how does a 4 stroke dirt bike engine work

I’d love to hear from you. Tell us about your adventures of dirt biking in the comments below. Please also share your photos. Either from your cameras or videos from your Gopro’s!

If this article hasn’t answered all of your questions. If you have more questions about dirt biking (or specifically about how does a 4 stroke dirt bike engine work), please comment below with your questions.

There will also be many more articles about dirt biking for you to read and learn about this fabulous sport and hobby.

Have fun and be safe!